Category

Mono Printed Tinplate Color Printed Tinplate Lacqured Tinplate Electrolytic Tinplate Tinplate Sheet Tinplate Coil Mr Tinplate SPCC Tinplate Tinplate Steel Coil

Features of Tinplate Products 1.Excellent Corrosion Resistance 2.Excellent Paintability & Printability 3.Excellent Solde

Basic Info.

| Model NO. | TINPLATE SHEET |

| Temper | T1-T5 Dr8-Dr10 |

| Service | Printing, Lacquering |

| Annealing | Ba/Ca |

| Tin Coating | 1.1-11.2 Grams/M2 |

| Surface | Bright, Stone, Silver, Matte |

| Thickness | 0.15-0.55mm |

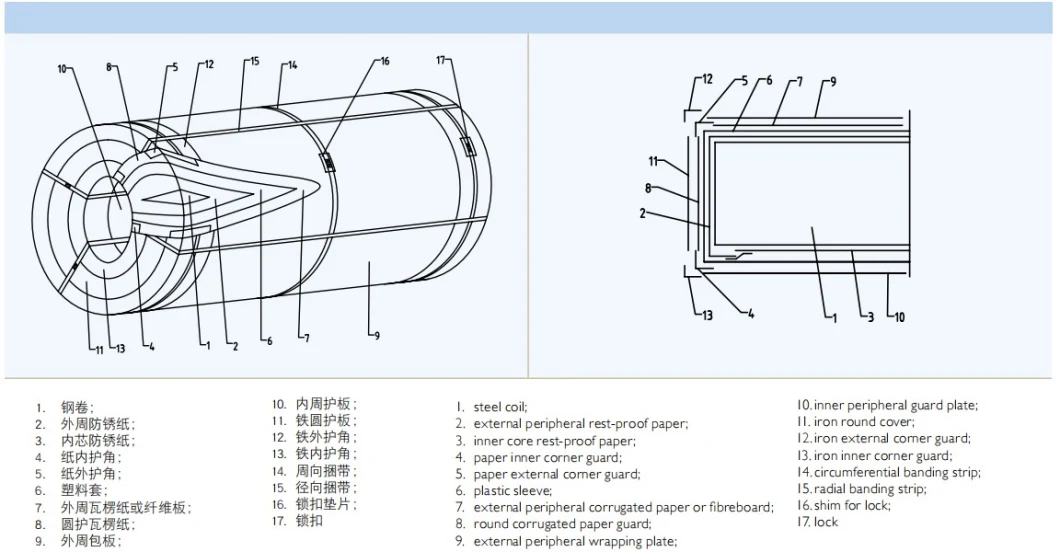

| Transport Package | Galvanized Steel Cover, Fumigated Wooden Pallet |

| Specification | Tinplate in sheets |

| Trademark | ZhongXin |

| Origin | China |

| HS Code | 7210120000 |

| Production Capacity | 250000 Tons Per Year |

Product Description

Features of Tinplate Products1.Excellent Corrosion Resistance

2.Excellent Paintability & Printability

3.Excellent Solderability & Weldability

4.Excellent Formability & Strength

5.Beautiful Appearance

Available Specification:

| Thickness & Tolerance | 0.14-0.55mm (tolerance: +/-0.002mm) | |

| Width & Tolerance | 712mm-1050mm (tolerance: -0/+3mm) | |

| Temper | Single reduced | T1, T2, T3, T4, T5 |

| (BA & CA) | Double-reduced | DR8, DR9, DR10 |

| Coil I.D. | 420mm, 508mm | |

| Weight | 1-1.5MT/bundle, 4-10MT/coil | |

| Surface Finish | Bright, Stone, Silver, Matte | |

| Tin coating | Equal tin coating | 1.1/1.1,2.0/2.0, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2 |

| Different tin coating | 1.1/2.8, 2.8/5.6, 5.6/8.4, 8.4/11.2 | |

Standard:

| Standard | Q/BQB 455-2007 | JIS G3303-2002 | EN 10202-1989 | EN 10202-2001 | ASTM A657M-2003 |

| Single Reduced SR | - | T-1 | T50 | TS230 | T-1 (T49) |

| T-2 | T-2 | T52 | TS245 | T-2 (T53) | |

| T-2.5 | T-2.5 | - | TS260 | - | |

| T3 | T-3 | T57 | TS275 | T-3 (T57) | |

| - | - | - | TS290 | - | |

| T4 | T-4 | T61 | TH415 | T-4 (T61) | |

| T5 | T-5 | T65 | TH435 | T-5 (T65) | |

| Double Reduced DR | - | - | - | TH520 | DR-7.5 |

| DR-8 | DR-8 | DR 550 | TS550 TH550 | DR-8 | |

| - | - | TH580 | DR-8.5 | ||

| DR-9 | DR-9 | DR 620 | TH620 | DR-9 | |

| DR-9M | DR-9M | DR 660 | DR-9.5 | ||

| DR-10 | DR-10 | - | - | - |

Surface:

| Marks | Surface state | Characteristics |

| B | Bright | roughness: 0.13~0.33um |

| R | Stone | roughness: 0.24~0.69um |

| S | Silver | roughness: 0.77~1.27um |

| M | Matt | roughness: 0.77~1.27um |

Tin Coating:

| Classification | Designation oftin coating weight | Nominal tin coating weight(g/m2) | Min average tin coating weight(g/m2) |

| Equal tin coating(E) | 1.1/1.1 | 1.1/1.1 | 1.8 |

| 2.2/2.2 | 2.2/2.2 | 4 | |

| 2.8/28 | 2.8/28 | 5 | |

| 5.6/5.6 | 5.6/5.6 | 10.5 | |

| Differential tin coating(D or A) | 2.2/1.1 | 2.2/1.1 | 2.0/0.9 |

| 2.8/1.1 | 2.8/1.1 | 2.25/0.9 | |

| 5.6/1.1 | 5.6/1.1 | 5.05/0.9 | |

| 2.872.2 | 2.8/22 | 2.25/2.0 | |

| 5.6/22 | 5.672.2 | 5.05/2.0 | |

| 5.6/2.8 | 5.6/2.8 | 5.05/2.25 |

Oiling: If no engagement, tinplate electro statically oiled with DOS(0.5-10mg/m2).