Category

Lamianted Tinplate Steel Coil for Chemical Can/Paint Bucket

Lamianted Tinplate Steel Coil For Chemical Can/Paint Bucket Production Description:Laminated steel is a kind of composit

Basic Info.

| Model NO. | LS-P |

| Stock | Stock |

| Transport Package | Standard Export Packing |

| Specification | 0.15-1.0MM*600-1250MM |

| Trademark | LS-C |

| Origin | China |

| HS Code | 7210120000 |

| Production Capacity | 6000tons/Month |

Product Description

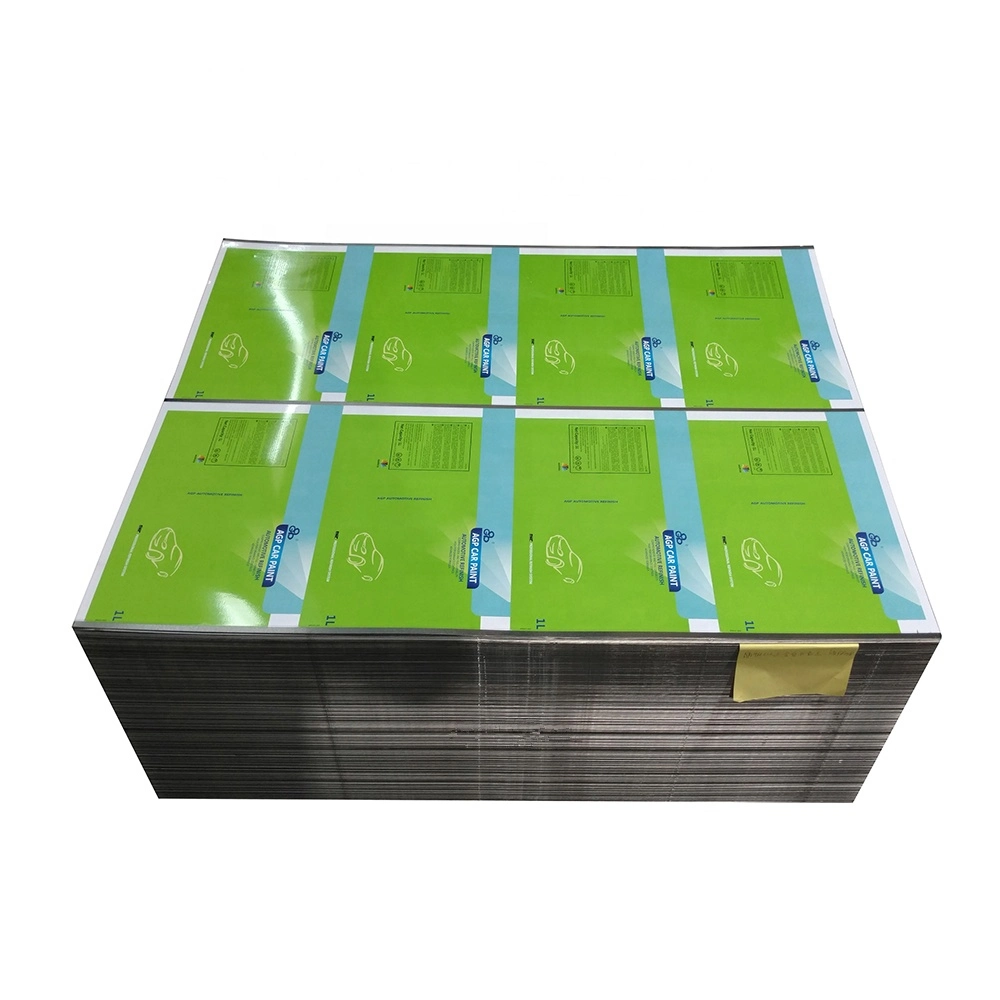

Lamianted Tinplate Steel Coil For Chemical Can/Paint Bucket

Production Description:Laminated steel is a kind of composite materials adopt the plastic film after color printing and cold rolled sheet combined with(melting or bonding),which is to replace the traditional printing on mental plates.Adopt plastic film(PET,PP,PE) combined with metal plate through hot melting or bonding,which has solved the corrosivity of metal plate and metal container,both has the decorating,barrier of plastic film and the malleability, figurability of metal.Specifications:Raw material: tinplate, chromium plated iron, galvanized sheet, black platePlastic film:PET, PP, PE, Resin-film etc.Thickness: 0.15-0.40mmWidth: 600-1050mmFilm color:White film, transparent film, aureate film, color film, laser film and so on film color White film 15-30μTransparent film 8-30μGold film 8-30μApplication:We can customize the pattern according to your plate-making documents. Laminated steel has a good application prospect in the market of packaging materials such as stamping cans DRD, punching cups DI and so on, special-shaped cans, easy to open and tear covers, which also provides personalized and fashionable packaging materials for food cans, various drinks, grease chemical industry, daily chemistry, medicine and health care.Application fields 1.Construction: Roofing, walls, ventilation ducts, rain troughs, sewers, etc. 2.Container manufacturing: Containers for producing petroleum and barrels for containing different kinds of chemical raw materials, industrial troughs, water tanks, military bullet cases, fermentation vats for beer, barns, distribution cabinets, containers, fertilizer boxes, etc. 3. Household appliances, furniture: Backboards shells of washing machine, refrigerator, air conditioning and dust collector; Wardrobes, tables, night tables, file cabinets, file boxes, book shelves and other furniture. 4.Vehicle and vessel manufacturing: Shells and internal structural parts of cars, trains and other vehicles. Top covers and partitions of vessels. Others: Machinery structural parts, manufacturing shells of motor, different kinds of smoke tubes, pipes, mechanized refrigerated warehouse, etc. Chemical cans:Chemical can,lacquered can,paint bucket,three aerosol can,easy open can,top or bottom cover.Food metal cans:Food can,beverage can,tea pot,candy cans.Decorative cans:Gift box,jewel case,stationery case,cigarette case,wine case.Other cans:Building board,paint brush,mobile phone accessories,etc. Film laminated steel VS Traditional printing iron:Increase securityThe film is directly applied to the metal surface and no longer use various solvents to solve the problems of bisphenol A.Excellent processing performanceProcessing resistance, abrasion resistance, not easily be damaged during processing.High chemical resistanceAgeing resistant, corrosion resistant, can adapt to the harsh environment without shedding and rusting, low volatile, no water consumption.Green, energy-saving and pro-environmentSimplify the drying and fixing process, greatly reduce the energy consumption and CO2 emissions.Saving costs during canning processRemove the inner coating and base coating, simplify the canning process, save costs.Manufacturing process and process simpleManufacturing process and process simple, clean, efficient, low energy consumption, low carbon, low volatile, no water consumption;Manufacturing process and process simpleManufacturing process and process simple, clean, efficient, low energy consumption, low carbon, low volatile, no water consumption;Saves a lot of equipment investment and labor costCompared to traditional tinplate printing coating, less equipment, less investment, covers an area of less, use less workers.For more infomation,please contact below.Joyce Overseas SalesTel:+86-15252633996 0510-83596646