Category

0.12

1. Brief IntroductionIt is a plain carbon steel sheet coated in a galvanizing process that applies a barrier of zinc toi

Basic Info.

| Model NO. | 0.12-0.8*665/800/820/840/900mm |

| Technique | Cold Rolled |

| Application | Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate |

| Special Use | Cutting Tools, Measuring Tools, Cutters in Common Steel, High-strength Steel Plate, Wear Resistant Steel, Silicon Steel |

| Stock | Stock |

| Base Material | Cold Rolled Steel Coil |

| Usage | Roofing, Sandwich Panel, Cladding |

| Surface | Chromate/Oiled/Dry/Passivated |

| Spangle | Regular,Large,Small,Mini Spangle |

| Package | Standard Seaworthy Export Packing |

| After Corrugate | 665/800/840/900/1050mm |

| Tolerance | T:+/-0.02mm; W:+/-2mm |

| Lifetime | 10-20 Years |

| Material | Dx51d, SGCC, Sgch |

| Thickness | 0.12-0.8mm |

| Place of Origin | China (Mainland) |

| Tile Type | Corrugated, Trapezoidal, Glazed, etc |

| Zinc Coating | 40G/M2-275G/M2(G30-G60) |

| Length | 1.8m-11.8meters |

| Width | 665-1020mm |

| Transport Package | Seaworthy Export Package |

| Specification | 0.12-0.8mm |

| Trademark | TIGA |

| Origin | China |

| HS Code | 72107010 |

| Production Capacity | 200, 000 Tons/Year |

Product Description

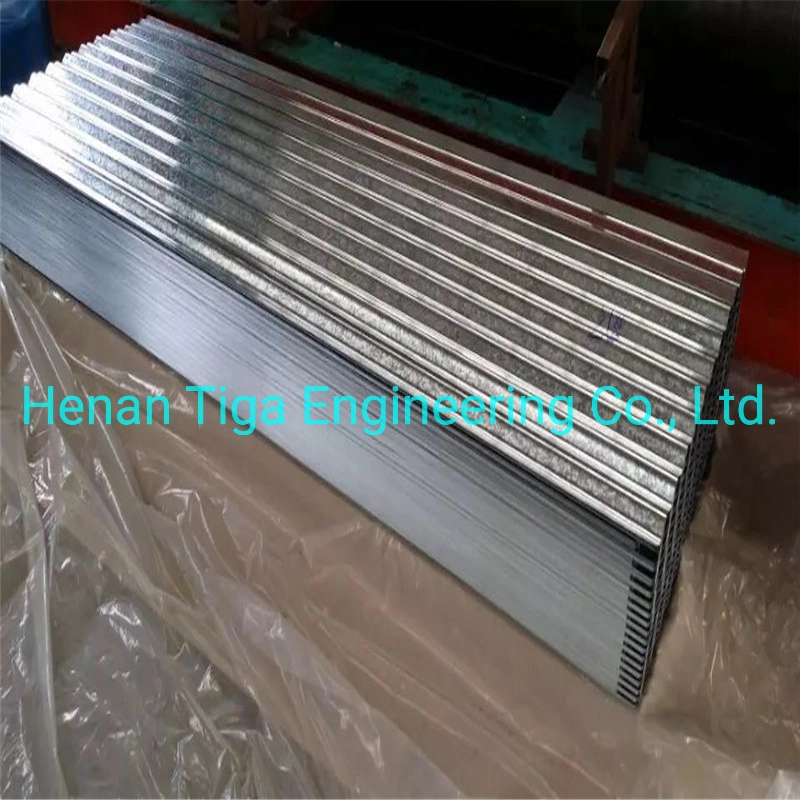

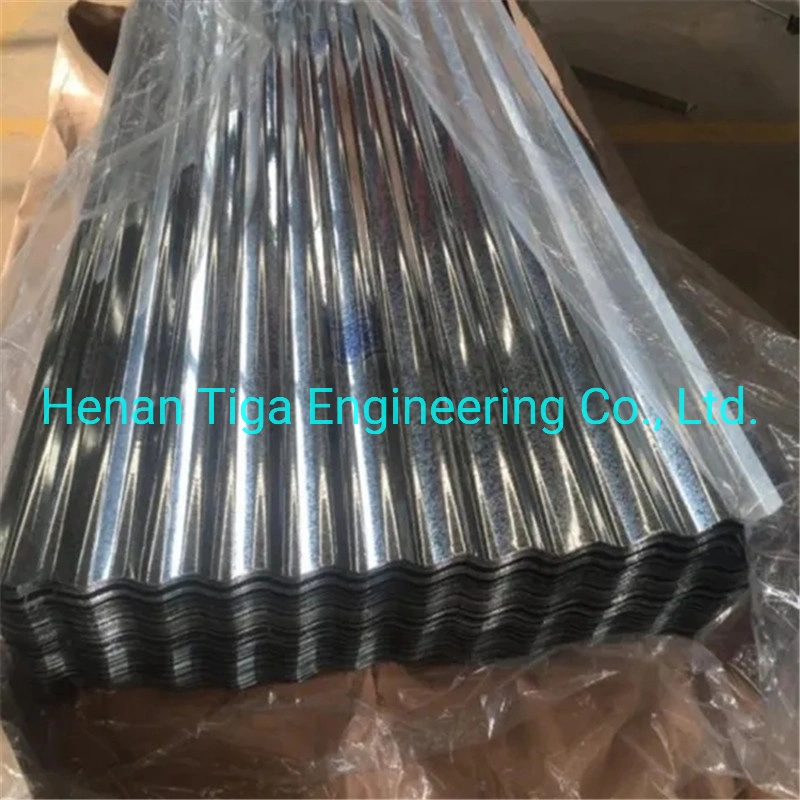

1. Brief IntroductionIt is a plain carbon steel sheet coated in a galvanizing process that applies a barrier of zinc toinsulate it from the elements. Most of the corrugated roofing and siding products seen todayand for many years past are made with a galvanized finish2. Roofing Sheet FinishAs with almost any product the finish of the galvanized metal finish will change over time. Aftera period of time, the surface will appear to have a white oxide look. When this happens thematerial is actually protecting itself from further damage. We stock and sell several corrugatedand decking panels in either a (G-60) or (G-90) level of galvanizing3. Application scopeIt is most commonly used for commercial, agricultural, and industrial purposes, however, it isnow also being recognized as an excellent form of residential roofing4. AdvantagesA normal steel sheet will rust almost immediately, but galvanizing will protect the steel. Thisgalvanized, eltro-coated, hot-dipped process produces a silvery look or spangled finish. Asa standard, several of our industrial metal siding, metal roofing, metal decking, corrugatedmetal panels and accessories are made in galvanized steel5. Technical ProcessingHot rolled steel coil -->Cold rolled- >hot dipped galvanized/ galvalume- > corrugated-->packing6. Common size as follows1) 762mm to 665mm(ater corrugated)and 9 waves2) 914mm to 750mm(after corrugated)and 11 waves3) 1000mm to 890 or 900mm(after corrugated and12or14waves| Product | Hot Dipped Galvanized Corrugated Steel Iron Roofing Sheet |

| Base material | Hot dipped galvanized steel sheet; Hot dipped galvalume steel sheet |

| Material Grade | SGCC / SGCH / DX51D+Z / DX51D+AZ, etc |

| Thickness | 0.12-0.8mm |

| Width before corrugation | 750mm,762mm,800,900mm,914mm,1000mm ,1200mm |

| Tolerance | Thickness: +/-0.02mm Width:+/-2mm |

| Zinc-coating | 40g/m2-275g/m2(G30-G60). |

| Technique | Hot rolled steel coil > Cold rolled>hot dipped galvanized>corrugated |

| Terms | Raw material width 762mm,after corrugated width 665mm:9 waves Raw material width 914mm,after corrugated width 800mm:11 waves Raw material width 1000mm,after corrugated 890/900mm:12 or 14 waves |

| Feature | Roofing Steel Sheet have excellent performance of decoration, corrosion resistance etc. |

| Export package | Waterproof paper, galvanized steel covered and steel strip packed |